"Better Weigh"® Continuous Weigh Feeders Control

For gain, loss or continuous weighing applications

Overview

Metalfab "Better-Weigh®" Feeder Controls are available with a "Gain in Weight" mode for applications where a product is being fed into a scale system such as a container sitting on a floor/bench scale or weigh hopper on load cells. In this mode, the controller can verify the zero setting between weighments, auto-tare the weight of a container, verify the container is in position by referencing the container weight setting, or a band value plus or minus to confirm an empty container is in place prior to start of feeding.

A "Loss-in-Weight" mode can be provided for applications where the feeding device is on load cells or a scale system of some type. This mode is used when one or more products need to feed into a process simultaneously, allowing all feeders to dispense product at the same time.

A "Continuous Weighing" mode is provided to continually feed product at a preset rate on a per-second, per-minute, or per-hour basis. Refilling of the feeder can be automatic through input of minimum and maximum weight values to the controller.

Features/Benefits

- Automatic batching or continuous feed rate control

- Automatic feed rate optimization for fast and slow speed settings as well as dribble point determination are performed automatically

- Automatic pre-act (material in suspension compensation) adjustment

- Automatic JOG feature to bring batch into tolerance

- Analog output to represent weight or feed rate as standard

- Additional Analog outputs available for weight or feed rate as needed

- Batch history (or rate logging) to archive the previous 200 records. Rate logging can be set for time intervals as needed

- System alarm output

- Security includes two levels of password protection

- Tolerance checking with different parameters for under and over tolerance settings

- Remote start and stop contacts provided

- Can "Abort" or "Resume" a batch after E-stop

- Standard unit includes 12 outputs and 12 inputs to control equipment. Some are preprogrammed for specific applications

- Analog input options available for remote entry of batch size or feed rate from remote PLC or DCS

- Communication options include but are not limited to: Ethernet I/P, Device Net, DH Plus, DH-485, DF1 Half, and DF1 Full Duplex

Please Note: Custom programming can be provided to control additional upstream or downstream equipment as needed.

Operating Characteristics

- Handles powders, pellets, flakes, and other dry materials where it is necessary to determine actual feed rates on a loss-of-weight basis

Specifications

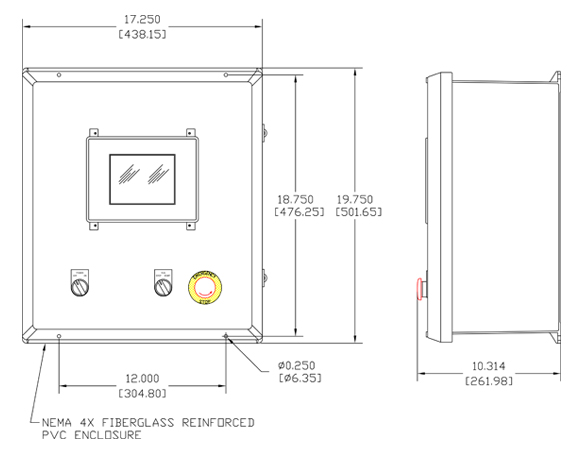

Dimensions

Model BWP/L "Better Weigh"® Batch Feeder

- Enclosure: NEMA 4X

- Display Type: 6" Color, TFT, QVGA touch screen

- Screen Pixels: 320x240

- Power: 120 VAC @ 2 Amp 1 ph 50/60 Hz (does not include product feeder) Typical consumption 0.30 Amp @ 120 VAC (36 W)

- Operating Temperature: 32 to 113°F (0 to 45°C)

- PLC Type: Allen Bradley

- Bin Activators

- Posibins & Bins

- Bulk Bag Unloader

- Gravimetric Feeders

- Volumetric Feeders

- Conveyors

- Bag Dump Hopper

- Automatic Bag Slitter

- Spin Loader

- Portable (IBC) Bin Unloaders

- Wetting Cone

- Integrated Systems and Subsystems

Activated Carbon Injection

Activated Carbon Injection Dry Solids Processing

Dry Solids Processing Custom Fabrication

Custom Fabrication

Website

Website